INDUSTRIAL

WATER TREATMENT

Industrial water treatment involves a series of procedures or processes that treat water before it is used within an industrial facility. The treated water is used to enhance product development and protect equipment from scaling and corrosion. Water sources include food and beverage ingredient water, water used for sanitation, cooling tower makeup water and boiler feed water.

CECO works alongside our industry partners to develop systems that filter, soften and purify through the removal of dissolved solids and heat for sanitization use. Contact us for specific technology information and learn how the CECO team can enhance the water treatment process in your facility.

Meet sustainability goals – treated water reduces the volume of process water needed and protects equipment

INDUSTRIAL

WATER TREATMENT

Meet sustainability goals – treated water reduces the volume of process water needed and protects equipment

Industrial water treatment involves a series of procedures or processes that treat water before it is used within an industrial facility. The treated water is used to enhance product development and protect equipment from scaling and corrosion. Water sources include food and beverage ingredient water, water used for sanitation, cooling tower makeup water and boiler feed water.

CECO works alongside our industry partners to develop systems that filter, soften and purify through the removal of dissolved solids and heat for sanitization use. Contact us for specific technology information and learn how the CECO team can enhance the water treatment process in your facility.

Treatment Types

media filtration

Media filtration is a method of filtering sediments, particulates and turbidity from water by applying pressurized feed water to push liquid through filtration media. Different media types are used depending on what kind of contaminants are removed.

Reverse Osmosis

Reverse osmosis works to remove a percentage of the total dissolved solids. When used with water entering a facility, the reverse osmosis unit conditions the water, removing hardness ions, such as calcium and magnesium, as well as ions like salts.

Water Softening

Water softening removes hardness found in water in the form of minerals, such as calcium and magnesium (hardness). These minerals often build up on boilers, heat exchangers, piping and other equipment causing scaling and corrosion.

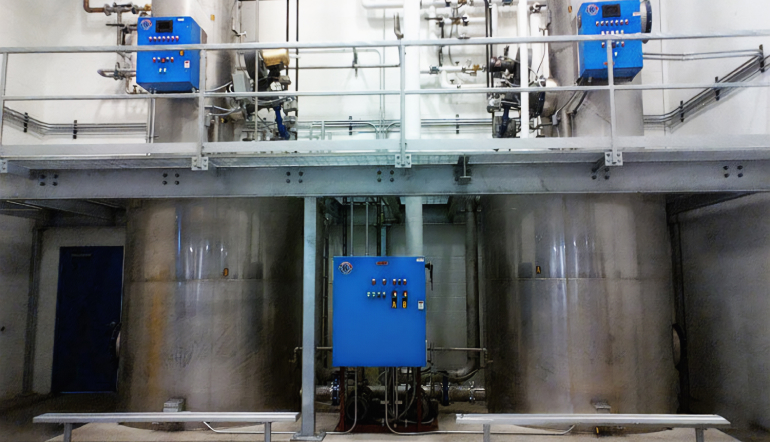

Water Heating

Water heating via a direct contact water heater. The direct contact water heater eliminates the need for steam and heats water in minutes.

Deminerilization

Deminerilization, the electro-deionization (EDI) process mainly produces (demineralized) high-purified water required for different industries, combining semi-impermeable membrane technology with ion-exchange media. The electrical current is used to continuously regenerate the resin, eliminating the need for using harsh chemicals required for the regeneration of ion exchange resin.

Technology Overview

CECO is a key part of helping meet the global demand for environmental and equipment protection through water treatment systems and solutions.

FRESH WATER REVERSE OSMOSIS

DUAL MEDIA FILTRATION

DIRECT CONTACT WATER HEATER

EDI TECHNOLOGY

FRESH WATER REVERSE OSMOSIS

LEARN MORE